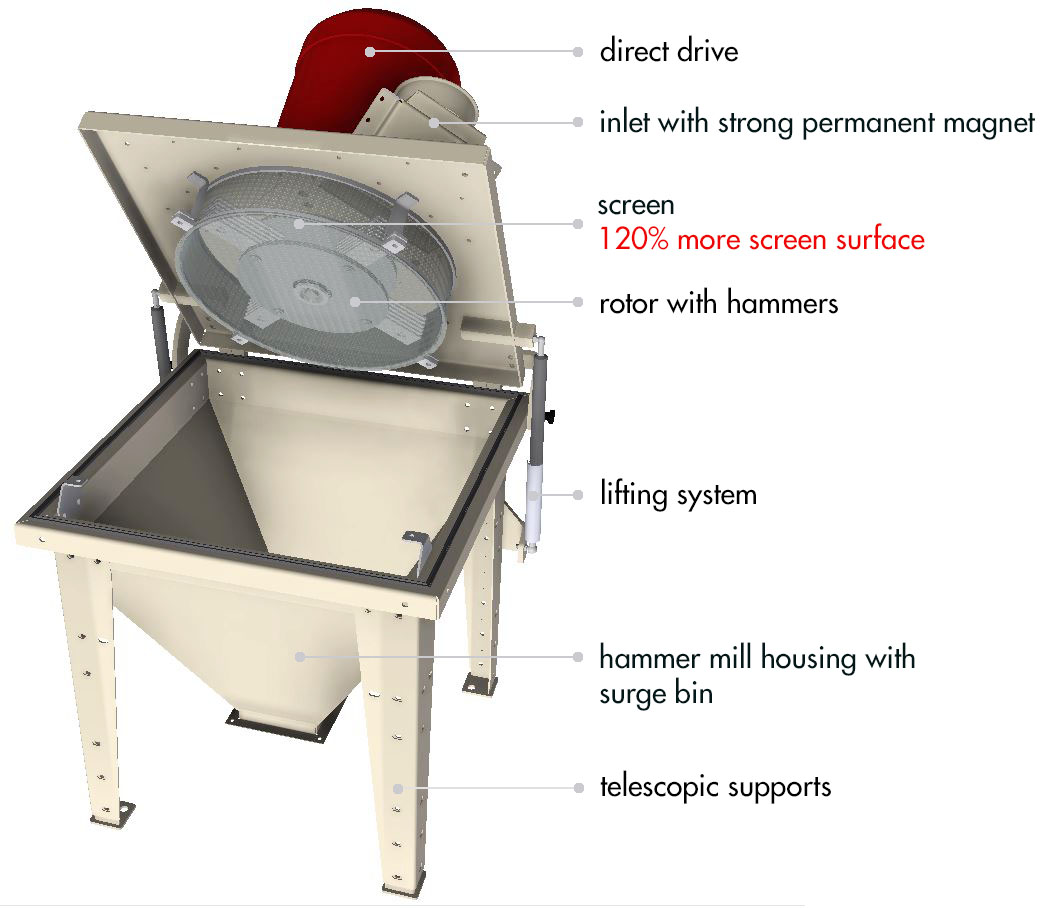

The hammer mill KHM can produce various ground material with high or low fines. The mill control automatically regulates the optimal feed and capacity utilisation for each produkt. Depending on the desired performance and structure, it may be useful to use several mills in parallel.

Your benefits

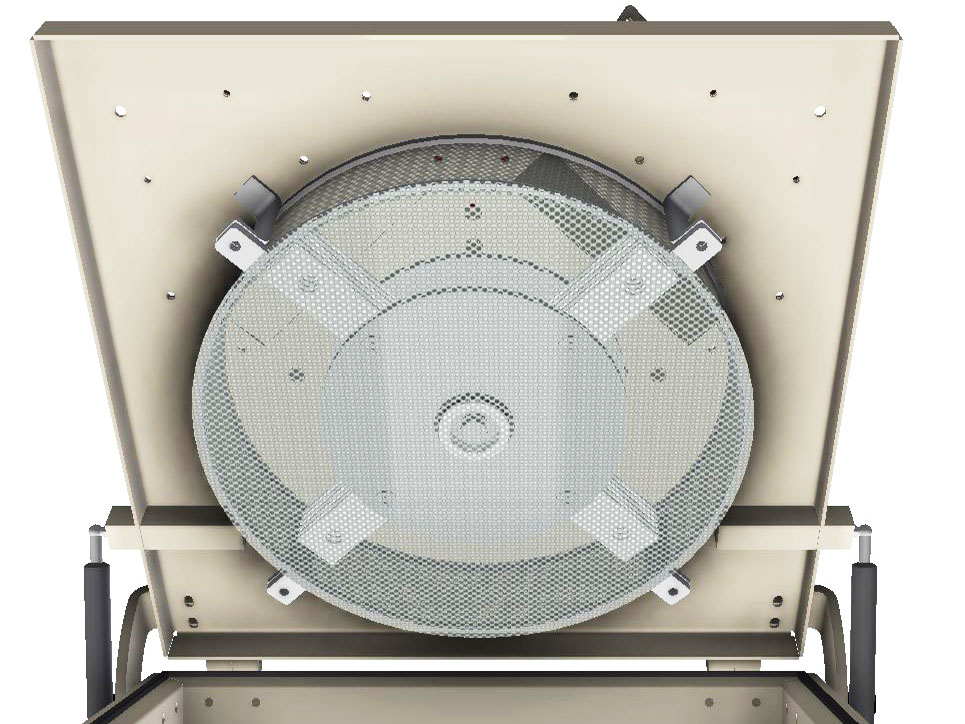

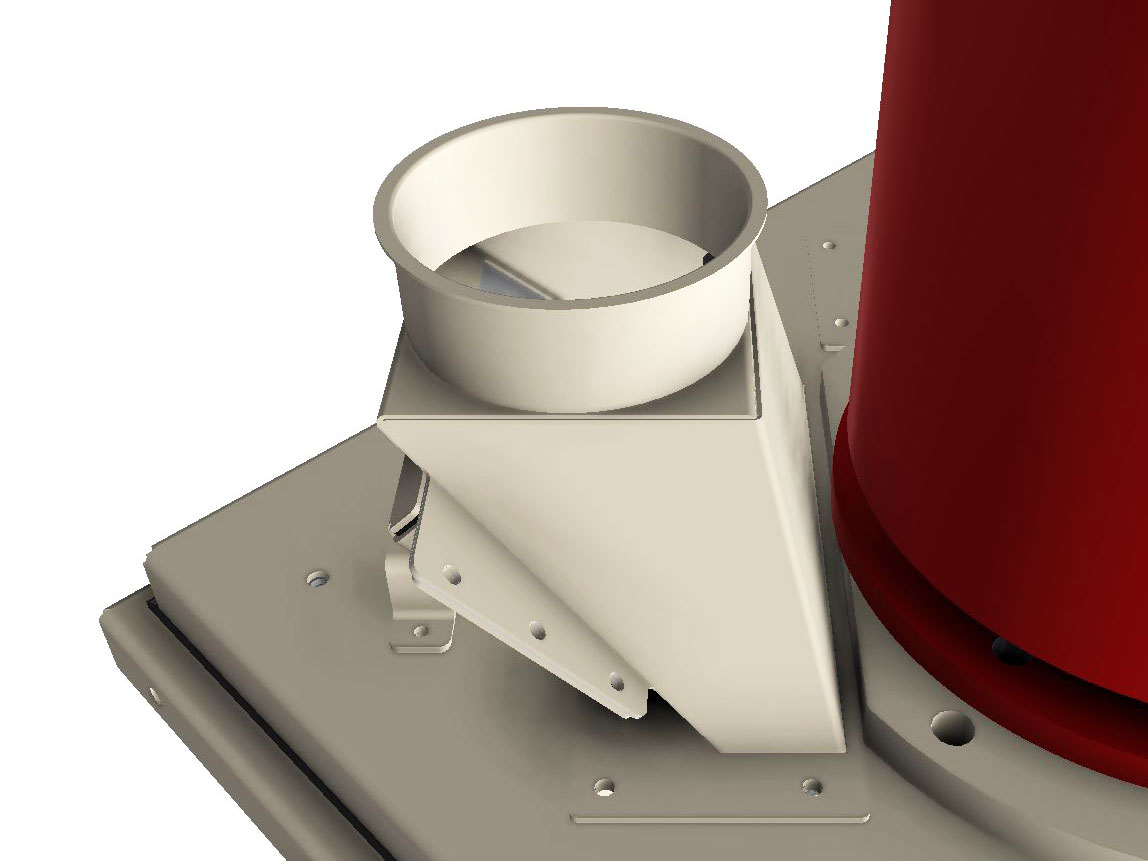

The hammer mill KHM is characterized in particular by their vertical grinding system, which has significant advantages against the conventional horizontal grinders. Because of the new construction of the screen the screen surface increases by 120% compared to the horizontal hammer mill. This leads to a higher capacity about 30% with the same driving power and an accordingly lower energy consumption. The large screen surface ensures lower temperatures during the milling process, so that the condensation is minimized. In addition, the lower temperature protect the vitamins and mineral substances. Also generates less turbulence and the formation of dust is reduced because the rotor rotates about the vertical axis. Thus, the use of a filter is not necessary.

This construction does not require a surge bin, because this is already integrated.

More benefits:

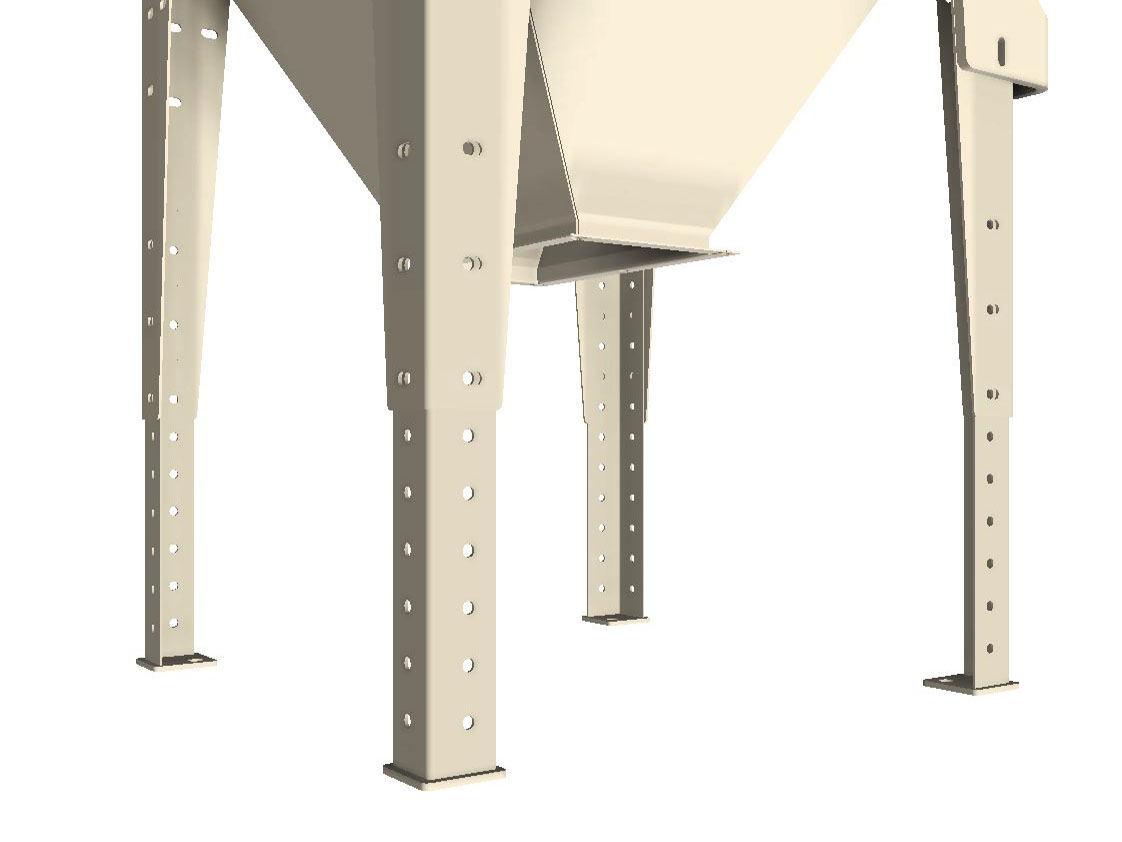

- Compact construction

- Infinietely height- adjustable supports

- Screen and hammers can construed in accordance with the product and customer request. For example a wire sieve, hole sieve or bat with hart metal insertion.