Functional description

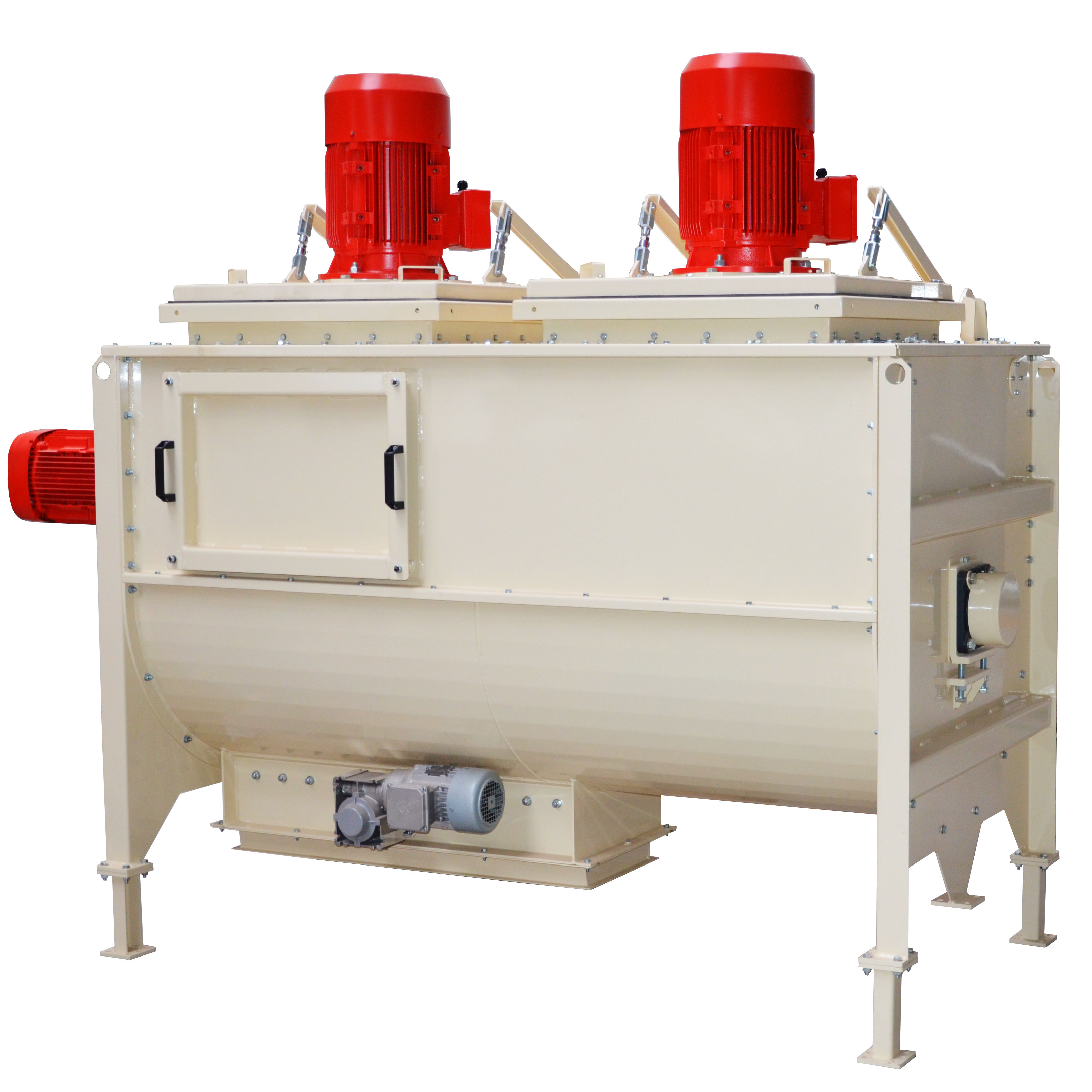

A screw transports the grain in one mill or optional in both mills at the same time.

The screw to the mill is regulated automatically depending on the load via a frequency converter.

The milled product falls directly into the underlying mixer and is detected via the built-in weighing system.

At the same time it is mixed in the horizontal mixer. After a short mixing time, the discharge takes place through a large pneumatic slide on the mixer floor.

Your benefits:

- 2 different mesh sizes can be used simultaneously without screen change

- High grinding and mixing performance with very short follow-up times

- Low space requirements due to compact design

- Use of both mills simultaneously possible

- no filter necessary

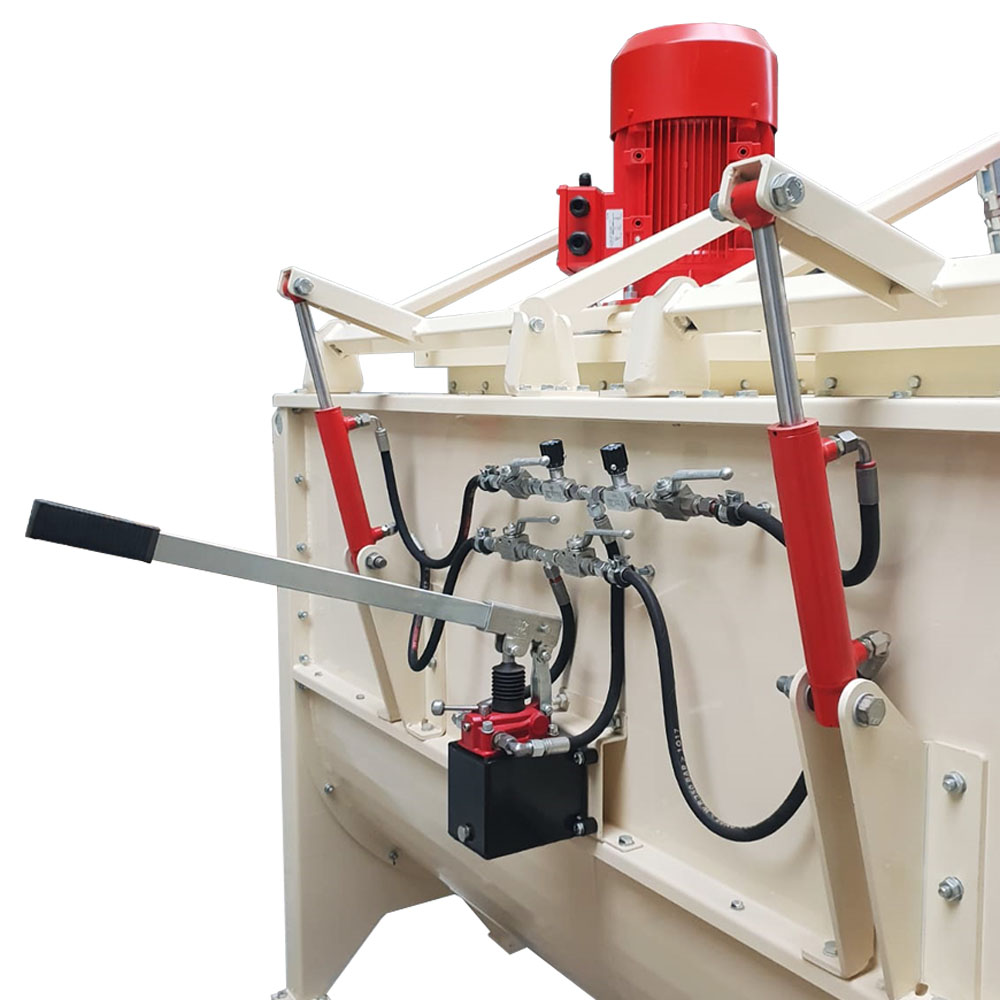

- remote controlled rack and pinion gear allows easy opening of the mill and thereby a quick screen change

- no conveyor from the mill to the mixer needed

- accurate and fast and gentle product mixing of the components through the use of the horizontal mixer

- faster discharge by large pneumatic slide

- Because of the short mixing time more batches can be processed per unit time.