Functional description

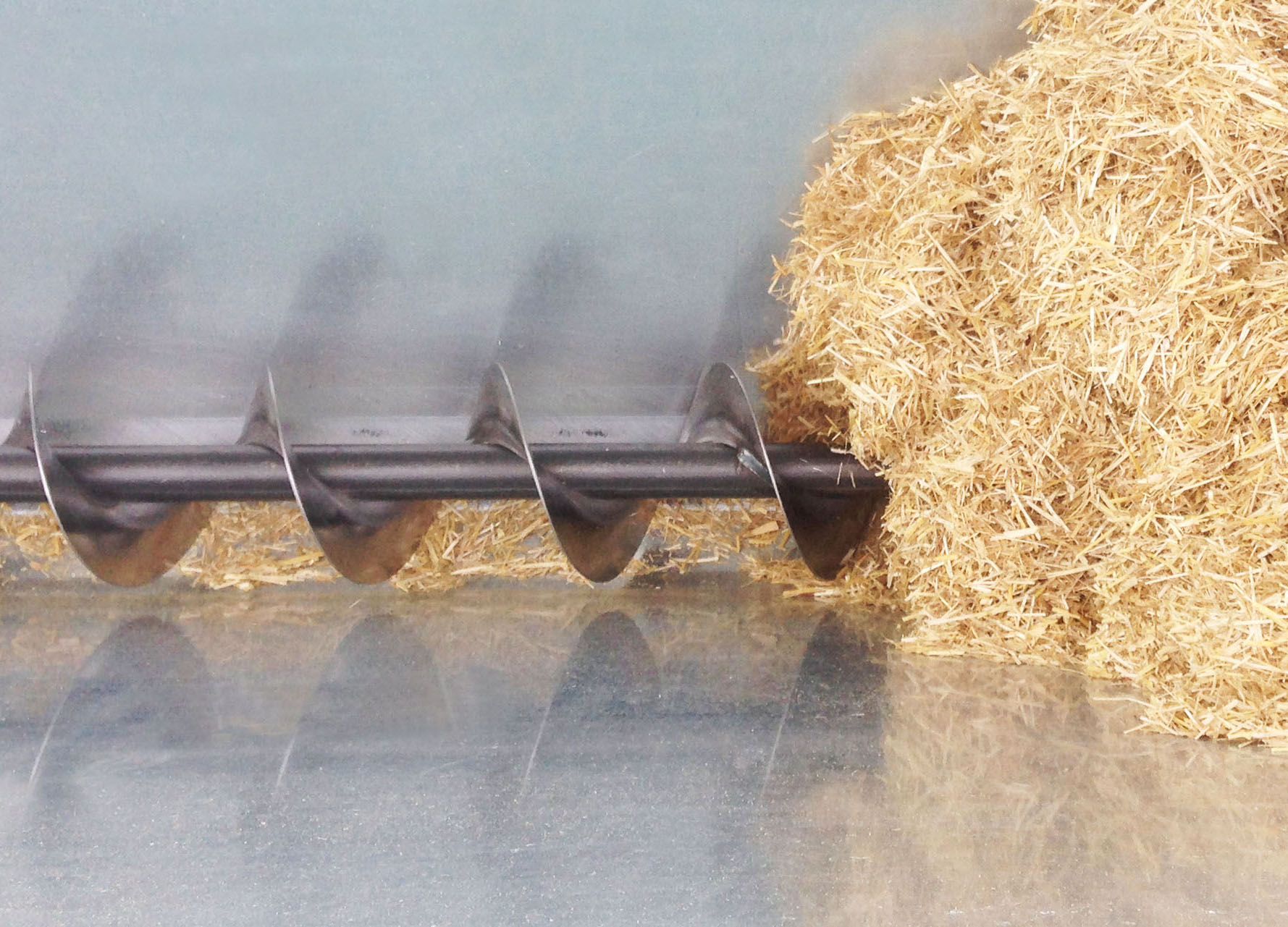

The intake of litter is made through a big buffer storage (figure 1) with screw conveyor (figure 3), which conveys the material towards the tube chain conveyor. (figure 4)

The conveyor pipes (figure 5) are installed in the areas which have to be covered with litter. By downpipes (figure 5) which end just over the ground the litter falls into the cubicles. Those downpipes serve as buffer tubes for the material. If one pipe is filled up the material is conveyed to the next downpipe. In this way all cubicles are filled sequentially. Several conveyor lines (figure 6) can be connected by transitions.

The special benefits

- Central intake

- Intake is made through a big buffer storage with screw conveyor

- The intake is usually located in front of the stable or in an outbuilding. In this way you don't always have to drive in and out of the stable while filling the litter system.

- More quietness in the stable because no driving or shunting in the area of the animals is necessary

- Temporally flexible or additional workforce are not necessary because the filling of the buffer storage is possible at any time

- No mobile litter box necessary

- Ideal for robotic stables because all cubicles are not always empty during the insertion of new litter

- Low-dust distribution of the litter because the litter spread gently from the downpipes

- Storage in the stable area by buffering in the downpipes

- Easy distribution of the litter at the end of the downpipes, largely by the animals themselves

- low maintenance